OEM, ODM, and OBM in the Disposable Tableware Industry: A Practical Guide for the U.S. Market

- abel zhao

- Jan 7

- 4 min read

The disposable tableware industry is often described as “manufacturing-driven.”But in reality, the business model behind manufacturing—OEM, ODM, or OBM—defines who controls pricing, margins, and long-term growth.

For U.S. importers, foodservice brands, distributors, and private-label sellers, understanding these three models is essential when sourcing disposable plates, cups, cutlery, and compostable food packaging.

This article explains OEM, ODM, and OBM specifically within the disposable tableware industry, with real manufacturing logic, cost implications, and strategic insights for the U.S. market.

What Is OEM in the Disposable Tableware Industry?

OEM Definition (Original Equipment Manufacturer)

OEM refers to a manufacturing model where the factory produces disposable tableware strictly according to the buyer’s specifications, while the buyer owns:

Product design

Brand name

Packaging artwork

Sales channels

The manufacturer focuses on production efficiency, quality control, and cost management.

In the U.S. disposable tableware market, OEM is the most common sourcing model, especially for:

Compostable products (PLA, CPLA)

How OEM Works in Practice

Typical OEM workflow:

OEM Advantages and Limitations

Aspect | OEM Strengths | OEM Limitations |

Cost | Lower unit cost at scale | Thin margins |

Risk | Low market risk for factory | High price competition |

Flexibility | Easy to switch suppliers | Low differentiation |

Brand value | Buyer-controlled | Factory builds no brand |

Industry reality:Most disposable tableware OEM factories operate on 5–15% gross margins, highly sensitive to resin or pulp price fluctuations.

What Is ODM in Disposable Tableware Manufacturing?

ODM Definition (Original Design Manufacturer)

ODM goes one step beyond OEM.

An ODM manufacturer designs the product first, then allows buyers to brand it as their own.

In disposable tableware, ODM usually means the factory owns:

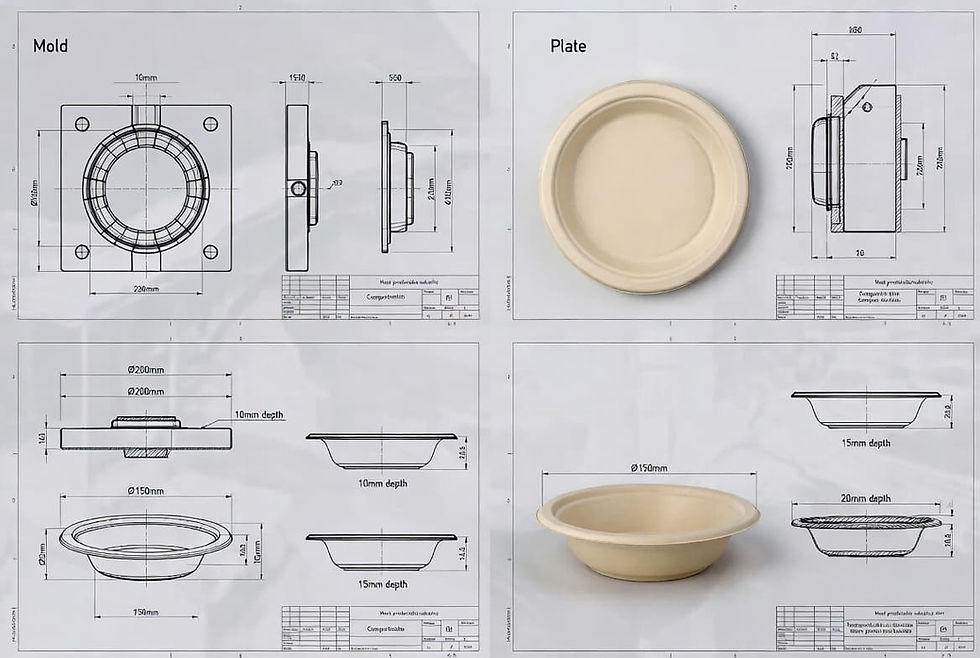

Product structure design

Mold development

Functional testing data

Existing SKUs ready for mass production

Buyers customize branding and packaging but do not start from zero.

Why ODM Is Growing in the U.S. Market

ODM is increasingly popular among:

Amazon FBA sellers

Foodservice distributors

Emerging eco-friendly brands

Key reasons:

Faster time to market

Lower development cost

Proven manufacturing feasibility

Reduced MOQ compared to full OEM customization

OEM vs ODM: Core Differences

Category | OEM | ODM |

Product design | Buyer-owned | Manufacturer-owned |

Mold cost | Buyer pays | Usually absorbed or shared |

Speed to market | Slower | Faster |

Differentiation | Limited | Moderate |

Original insight:In compostable tableware, ODM often provides better real-world performance because designs have already been tested for heat resistance, oil resistance, and structural strength—issues many first-time buyers underestimate.

What Is OBM in the Disposable Tableware Industry?

OBM Definition (Original Brand Manufacturer)

OBM refers to manufacturers that own and operate their own brand, controlling:

Product design

Branding and positioning

Sales channels and customer relationships

In the U.S. market, OBM companies sell not just products—but solutions.

How OBM Creates Value Beyond Manufacturing

OBM disposable tableware brands typically compete on:

Sustainability positioning

Regulatory compliance expertise

Supply chain stability

Consistent quality standards

They are often preferred by:

National foodservice chains

Institutional buyers

Long-term distribution partners

OEM vs ODM vs OBM: Strategic Comparison

Dimension | OEM | ODM | OBM |

Price control | Buyer | Buyer | Brand |

Gross margin | Low | Medium | High |

Customer loyalty | Low | Medium | High |

Market power | Weak | Moderate | Strong |

Long-term value | Limited | Transitional | Sustainable |

The Typical Upgrade Path in the Disposable Tableware Industry

Most successful manufacturers do not jump directly to OBM.

A realistic evolution path:

OEM → ODM → Hybrid OBM

Why a Hybrid Model Works Best

Many advanced manufacturers:

Maintain OEM volume for cash flow

Develop ODM product lines for differentiation

Operate OBM brands in selected markets

This structure balances risk, margin, and long-term brand equity.

OEM, ODM, and OBM in Compostable & Sustainable Tableware

Industry-Specific Insight (Original Content)

In compostable disposable tableware, the business model matters more than material choice.

Key factors often overlooked:

Certification maintenance cost (BPI, OK Compost)

Mold lifespan for bagasse products

Performance trade-offs between PLA and fiber

Regional composting infrastructure in the U.S.

ODM and OBM manufacturers are typically better positioned to handle these complexities, while pure OEM suppliers may only meet minimum compliance, not long-term consistency.

FAQ

Is OEM cheaper than ODM or OBM?

Yes, at unit level. But OEM often results in higher hidden costs due to redesigns, quality disputes, and supplier switching.

Can a manufacturer be OEM and OBM at the same time?

Yes. Many large disposable tableware manufacturers operate multi-model structures.

Which model is best for entering the U.S. market?

Startups: ODM

Importers & distributors: OEM or ODM

Long-term brands: OBM or hybrid

Does ODM limit brand differentiation?

Only partially. Differentiation can still be achieved through packaging, bundling, compliance positioning, and supply reliability.

Final Thoughts for the U.S. Disposable Tableware Market

OEM, ODM, and OBM are not just manufacturing terms—they represent three completely different business strategies.

For companies sourcing disposable tableware in the U.S., understanding these models helps:

Control cost more effectively

Reduce supply chain risk

Build long-term brand value

For manufacturers like Mana Packaging, combining manufacturing strength with design capability and compliance expertise creates a competitive edge that goes far beyond price.

Email: abel@mana-eco.com

WhatsApp: +86 13867471335

We specialize in a full range of disposable tableware. With fully automated production lines and certifications like FDA, BPI, and OK Compost, we offer high-quality, eco-friendly tableware made from biodegradable materials such as sugarcane bagasse and PLA, committed to providing customers with more sustainable and environmentally friendly options.

Comments